Shivas builds pickling lines for the treatment of

batch units. These batch units, which are arranged in cages or in special

suspension arrangements, are dipped into the pickling acid or will be

sprayed with the acid. Hereby individual solutions are prioritized. Both the

form of the batch unit and the specific material standards require targeted

and exact estimation of the possibilities.

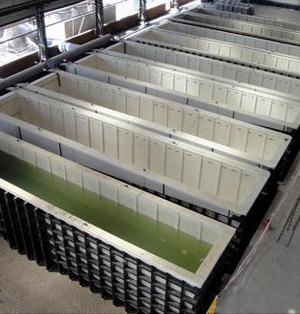

Shivas manufacture chemical Containment Tanks to customers’ exact

requirements. These can also incorporate integral lip extraction to

facilitate the efficient removal of fumes, especially where the chemicals

are heated. Tank heaters can be installed in a recessed base to assist in

more uniform heating of the chemical when compared with the side mounted

heater elements available. We manufacture and install all tank drainage

pipework, extraction ductwork and fume scrubbing systems.

Shivas builds tube pickling lines also called

compact units for low throughputs or completely tunneled pickling lines with

traversing mechanism or complex system control. The compact pickling line is

designed for small space requirements and simple operability. If required a

wastewater and a exhaust air treatment unit are integrated into the plant.

Pre-manufactured modules, which allow an extremely short construction time,

enhance the concept. Compact pickling lines can be used for simple

applications which require only approximately 2-3 treatment stages. Pickling

plants with several baths of diverse treatment stages are built for higher

throughput efficiencies.

The following treatment stages could be designed :

- Degreasing

- Rinsing

- Hydrochloric acid pickling bath

- Sulfuric acid pickling bath

- Activation

- Passivation

- Saponification

Depending on the throughput efficiency multiple immersions have to be

planned per stage. For the optimal use of the process levels, Shivas plans

an intelligent control of the immersions. This control system calculates the

optimal treatment sequences according to the principle of logic functions

and controls the plant according to that calculation.

Since many years Shivas engineers are working in

the field of wire pickling lines in continuous operation or immersed.

Shivas builds wire pickling lines also called compact pickling lines for

lower throughput or complete tunneled pickling plants with carrier and

complex process control. The compact pickling line is designed for small

space requirements and simple operability. For the collection of the arising

vapor the pickling goods are permanently exhausted by a traveling fume hood.

If required a wastewater treatment and an exhaust air treatment are

integrated into the unit. Prefabricated modules, which allow an extremely

short time of construction, enhance the concept.

Compact pickling lines can be used for simple applications, when only 2-3

treatment stages are necessary. For higher throughput efficiencies pickling

plants with several tanks of diverse treatment stages are planned.

The following treatment stages exist :

- Degreasing

- Rinsing

- Hydrochloric acid pickling bath

- Sulfuric acid pickling bath

- Activation

- Passivation

- Saponification

Depending on the throughput efficiency multiple immersions have to be

planned per stage. For the optimal use of the process levels, Shivas plans

an intelligent control of the immersions. This control system calculates the

optimal treatment sequences according to the principle of logic functions

and controls the plant according to that calculation.